Vacature: Commercieel medewerker binnendienst

Als Commercieel medewerker binnendienst biedt je ondersteuning aan ons Holaras verkoopteam. Een veelzijdige functie binnen een dynamisch team.

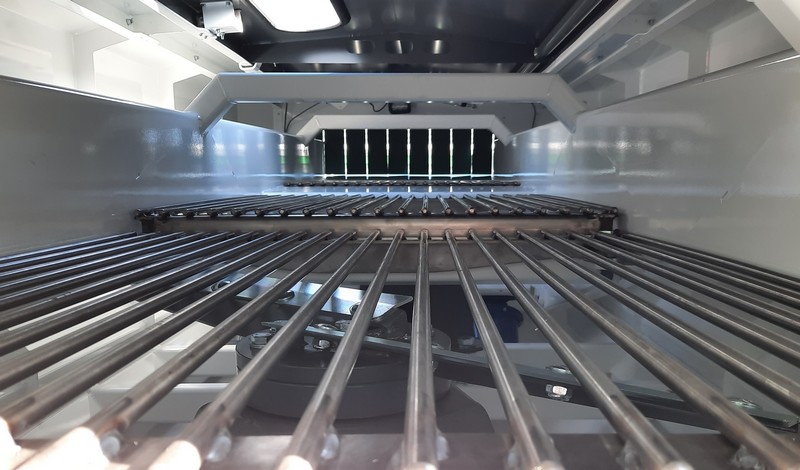

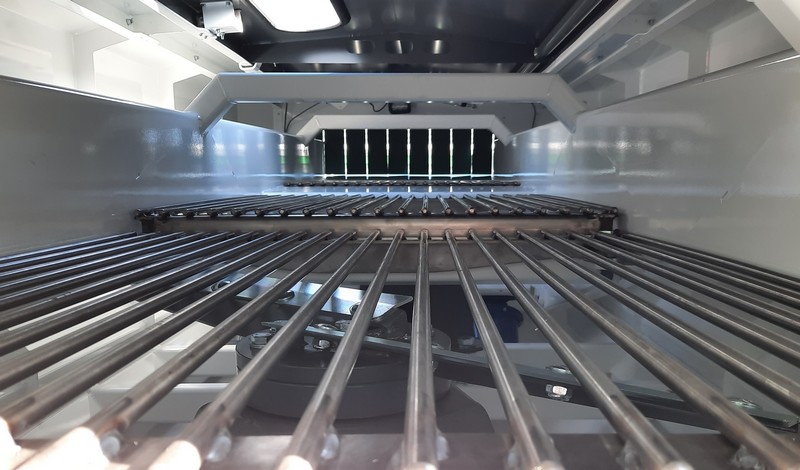

De uienafstaarter is speciaal ontworpen voor het afstaarten van uien en bloembollen. Door het hoge toerental en de speciale vorm van de messen ontstaat een sterke luchtstroom. Deze luchtstroom zuigt de uienstaarten tussen de spijlen van de trilzeef, waarna ze door de scherpe messen net onder de zeef afgesneden worden.

Alle uitvoeringen zijn leverbaar met gesloten luchtcirculatie en afvoerband. De afstaarters zijn voorzien van interne verlichting en worden standaard geleverd met een automatische schakelkast. De standaard doorvalmaat van een zeef is 28 mm.

In maart 2021 zijn de nieuwe uienafstaarters geïntroduceerd. Uniek aan deze vernieuwde lijn zijn de nieuwe triltechniek, het ergonomisch werken, de lichtere zeven en het snel kunnen wisselen van de robuuste zeven en messen (korte standtijd). De messen zijn staand vanaf de zijkant te wisselen door het openen van het grote dakluik. Het dakluik is voorzien van een volledig mechanische veiligheidsslot. Ook nieuw is de rubberen afscherming met het Foodsafe keurmerk. Wanneer stukjes rubber afbrokkelen, zijn deze detecteerbaar voor systemen in de voedselverwerkingsindustrie.

Alle uitvoeringen afstaartmachines zijn leverbaar met gesloten luchtcirculatie, afvoerband en een complete set zeven. Trilzeven voor speciale plantuien zijn als optie leverbaar. Andere mogelijke opties zijn een verhoogde onderbok en frequentie geregelde mesmotoren.

![]() Standaard

Standaard

![]() Optioneel

Optioneel

![]() Niet van toepassing

Niet van toepassing

| Type | AS 10 | AS 15 | AS 25 |

|

|

|

|

|

| Capaciteit | 5-10 ton per uur | 10-15 ton per uur | 20-30 ton per uur |

| Aantal messen | 2 | 3 | 6 |

| RVS | 2 | 3 | 6 |

| Open systeem, denk hierbij aan de veiligheidsvoorschriften | |||

| Variabele frequentie gestuurde trilmotoren | |||

| Variabele frequentie gestuurde mesmotoren | |||

| Separaat staande schakelkast | |||

| Diverse zeefmaten | |||

| Verlenging afvoerband | |||

| Afstandsbediening | |||

| Dempende invoer | |||

| Voorbereiding t.b.v. afzuiging |